In today’s competitive manufacturing industry, maximizing machine uptime is crucial for maintaining profitability. One often overlooked component that plays a vital role in machine performance is the spindle. The spindle is a critical element that drives many machine centers, directly impacting productivity and the bottom line.

When a spindle malfunctions, it can lead to costly delays, missed deadlines, and even equipment failure. This is why proactive monitoring and maintenance are essential to minimize downtime and control repair costs.

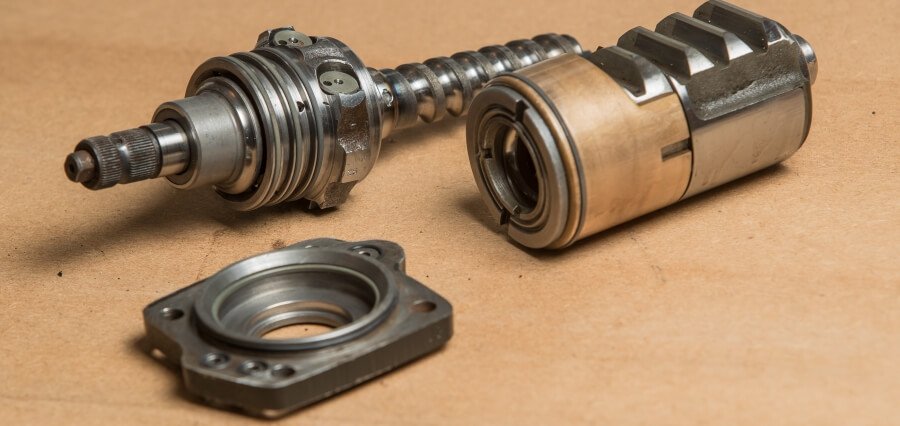

Understanding spindle repair is essential for maintaining peak operational efficiency. The spindle is the heart of many types of machinery, particularly in milling, turning, and grinding sectors. Regular use can cause the spindle to wear down over time, leading to inaccuracies and potential breakdowns.

Spindle repair services involve a thorough examination of the component to diagnose issues like misalignment, wear, or vibration. Technicians restore the spindle to its original condition or better through the repair process, ensuring machinery accuracy and reliability.

There are warning signs to look out for that indicate your spindle needs attention, such as increased vibration, reduced accuracy, abnormal sounds, and power loss or fluctuations. These signs can signify imbalances, worn bearings, or internal issues that, if ignored, can lead to more extensive damage.

The spindle repair process is meticulous and involves key steps such as assessment, disassembly, cleaning, repair or replacement of damaged parts, reassembly, and testing. Regular maintenance offers benefits such as extended equipment lifespan, enhanced performance, efficiency, cost savings, and safety for operation.

Investing in regular maintenance not only helps machines last longer but also ensures they operate at peak efficiency, contributing to faster production times and higher-quality outputs. By prioritizing spindle repair and maintenance, facilities can strategically enhance the performance and longevity of their machinery, ultimately leading to operational success.